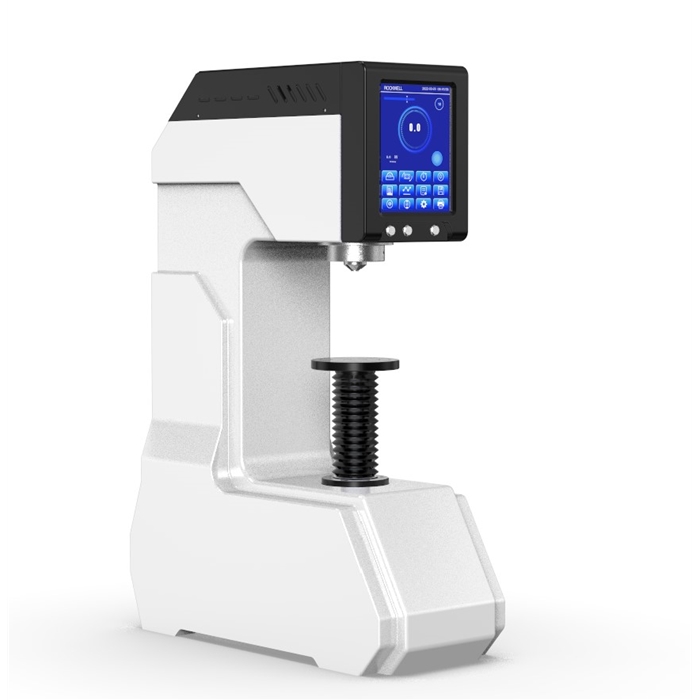

HRS-150ZD Automatic Rockwell Hardness Tester

Feature:

The equipment is an Electronic Loading Rockwell Hardness Tester. Press the start button, the workbench will automatically rise, and the equipment will automatically load and unload after the sample touches the indenter, and automatically display the hardness value, which can meet different Rockwell hardness test requirements. Novel appearance, complete functions, convenient operation, clear and intuitive display, stable performance.

1. 8 inch touch screen display, simple and convenient operation, can display and set the current test scale, test force, test indenter, load time, hardness conversion value etc;

2. It has all Rockwell test scales, including 15 kinds of Rockwell scales: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV; There are 6 kinds of superfical Rockwell scales: HR15N, HR30N, HR45N, HR15T, HR30T and HR45T, which can be converted between hardness scales;

3.Automatically apply the initial test force and the main test force, the application, maintenance and removal of the test force are automatically switched, and the operation is simple and rapid;

4.The test force is automatically compensated, and the accuracy of the test force is greatly improved; the high, medium and low hardness values are automatically corrected;

5.With the workbench automatic move up and down function, one key control the entire test process;

6.The fuselage is formed by a casting process and has been aged for a long time. Compared with the splicing process, the long-term use of small deformation, and can effectively adapt to a variety of harsh environments;

7.Car paint process, paint with quality high grade, anti-scratch ability, use for many years is still bright as new.

Application scope:

Suitable for quenching, quenching and tempering, annealing, chilled castings, malleable castings, hard alloy steel, aluminum alloy, copper alloy, bearing steel and other hardness determination. It is also suitable for surface quenching steel, material surface heat treatment and chemical treatment layer, copper, aluminum alloy, sheet, galvanized, chrome plated, tin plated materials, bearing steel, chilled castings, etc.

Technical parameter:

|

Model |

HRS-150ZD |

|

Initial test force |

3kgf (29.42N), 10kgf (98.07N) |

|

Total test force |

15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N), 60kgf (558.4N), 100kgf (980.7N), 150kgf (1471N) |

|

Indenter specification |

Diamond indenter,ф1.588mmBall indenter |

|

Test force application |

Automatic(loading/maintain/unloading) |

|

Auto-workbench |

Automatic rise, return, one key control |

|

Indication of Hardness Value |

Digital display touch screen to obtain hardness value |

|

Measurement scales |

HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRH、HRK、HRL、HRM、HRP、HRR、HRS、HRV、HR15N、HR30N、HR45N、HR15T、HR30T、HR45T |

|

Exchange scales |

HRA、HRB、HRC、HRD、HRF、HR15T、HR30T、HR45T、HR15N、HR30N、HR45N、HV、HK、HB |

|

Data output |

RS232 |

|

Resolution |

0.1HR |

|

Maintain time |

0~99s |

|

Max. Sample height |

320mm |

|

Distance from indenter center to machine wall |

180mm |

|

Power supply |

AC220V,50Hz |

|

Executive standard |

ISO 6508,ASTM E-18,JIS Z2245,GB/T 230.2 |

|

Overall dimension |

695*290*1000mm |

|

Net weight |

160KG |

Standard configuration:

|

Name |

Qty |

Name |

Qty |

|

Main machine |

1SET |

Diamond Rockwell indenter |

1PC |

|

ф1.588mmball indenter |

1PCS |

Medium and big flat workbench, V shape workbench |

1PC ea. |

|

Standard block 60~70 HRC |

1PC |

Standard block 20~30 HRC |

1PC |

|

Standard block 40~50 HRC |

1PC |

Standard block 80~100 HRB |

1PC |

|

Standard block 80~88HRA |

1PC |

Standard block70~85 HR30T |

1PC |

|

Standard block 65~80 HR30N |

1PC |

Fuse 2A |

2PCS |

|

Power cord |

1PC |

Dust cover |

1PC |

|

Product certificate |

1 COPY |

Product maunual |

1COPY |